Inside Common Motors (GM) between 1991 and 2014, Dr Shawn Gayden bought to see what was required to develop applied sciences as an R&D Lab Group Supervisor. As GM fashioned a three way partnership in China, she then bought to see how a enterprise is developed and a model is constructed. Throughout a keep in Japan, she took inventory of how Asian producers constructed their battery cells. And in her subsequent function at BP’s Castrol enterprise, she noticed first-hand the fossil-fuel associated challenges dealing with a spread of industries.

Whereas at GM, Gayden had began ruminating on an thought to ‘rewrite the subsequent era’ of battery manufacturing with a chilly plasma-based 3D printing method. It’s based mostly on an idea of taking present chemistry and materials, and making them producible at mass scales, at low price, whereas conserving the carbon footprint to a minimal. Gayden took the thought to her superiors at GM, outlining the potential it had. The response was that GM is a automobile firm, and as such this might be out of its remit, however Gayden was inspired to pursue it.

At this stage, Gayden had by no means thought-about going out on her personal to arrange a enterprise and a task at BP supplied an alternate subsequent profession step. It was merely a diversion on her journey. After simply 18 months, Gayden left BP, with the corporate’s blessing, to determine Intecells.

“We have to get out of the present course of which limits our means to make battery extra usable and longer vary whereas conserving prices down,” she tells TCT of her motivation. “Coming from business, realizing what it takes to take an idea to commercialisation, I used to be very acutely aware starting Intecells to search out prospects confirming my perception and my assumptions are correct. Since day one, each automobile firm, battery producer, all people loves the thought.

“They love the fee slicing aspect of this expertise, and the fee is the place I began, and in addition make it extra versatile by way of manufacturing footprint, your footprint naturally shrinks to 1 / 4 of the scale, which then lets you transfer across the globe. If you wish to put a battery manufacturing [facility] subsequent to your present plant, you are able to do that. If you wish to transfer it to Europe, Asia, to the US, you are able to do that.”

Gayden took an enormous step in the direction of commercialisation when she found Plasmatreat, a German firm whose plasma expertise is used for floor cleansing in transportation, electronics, packaging, shopper items and extra. Putting a partnership to leverage this expertise for her battery manufacturing wants, Gayden co-founded Intecells alongside Plasmatreat CEO Christian Buske in 2018. In 2019, the corporate procured enterprise capital funding and within the years since has constructed up a small group that may convey Gayden’s imaginative and prescient to the business world, alongside Plasmatreat and a choose variety of analysis teams.

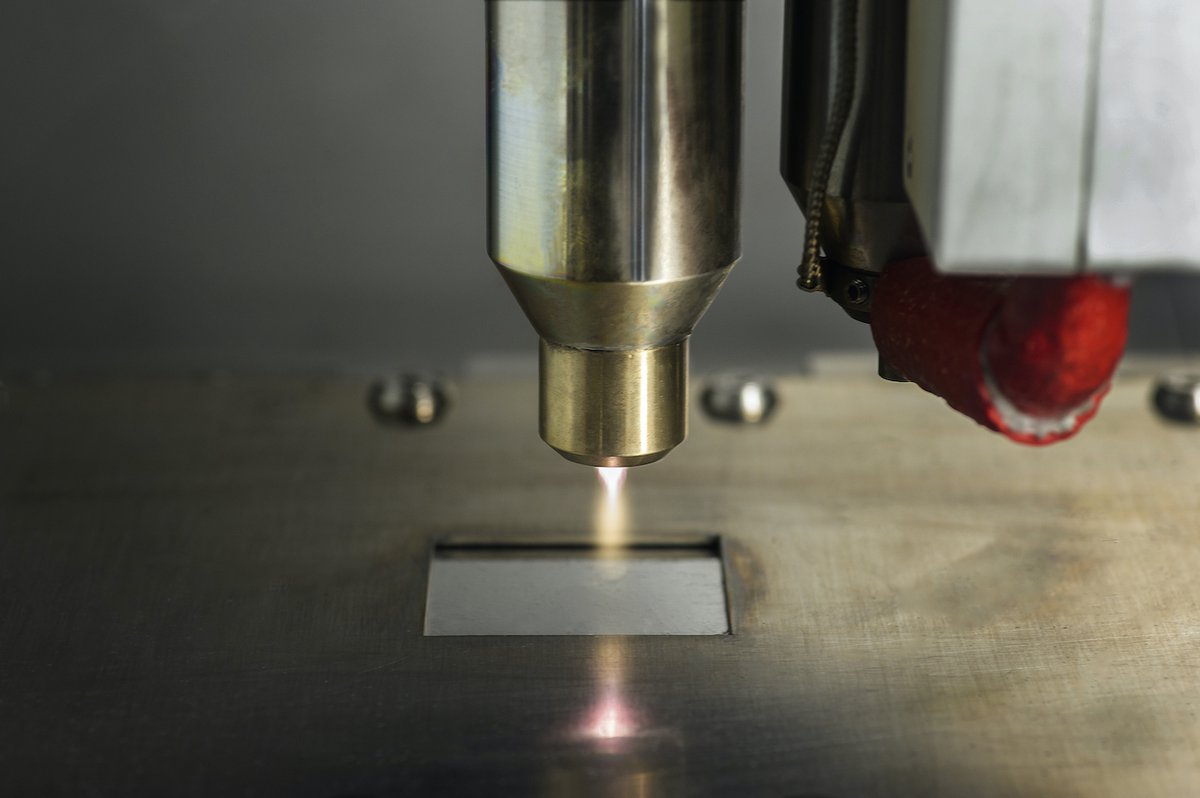

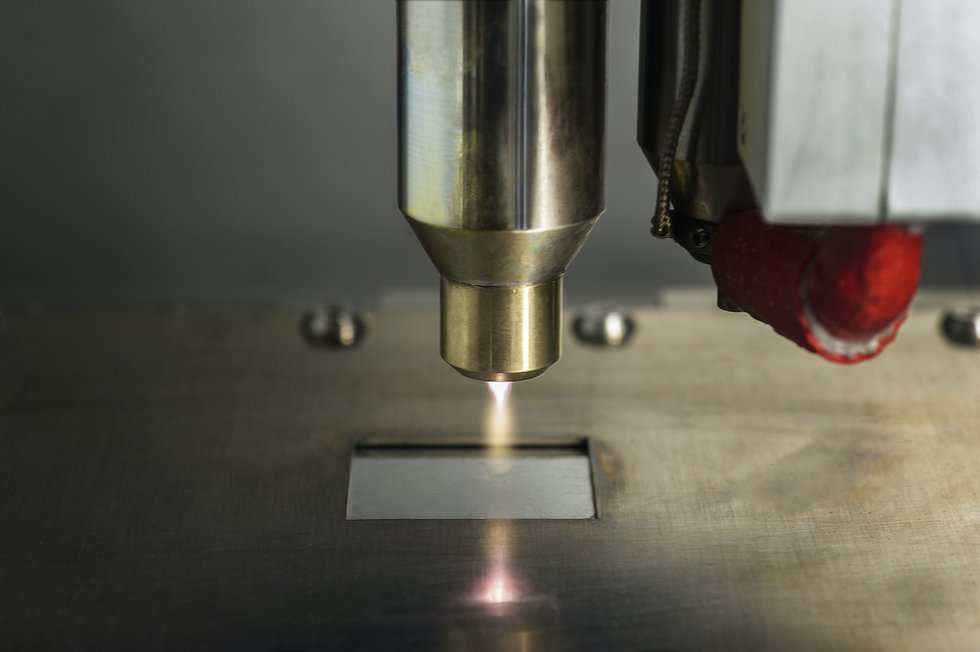

The expertise that Intecells is introducing sees a robotic arm deposit powder that’s then caught collectively by plasma to kind layers. The result’s the creation of batteries with 3D topologies which might be stated to return important enhancements to electrode coating adhesion (10x), vitality density and energy density (each 2x), and reductions to manufacturing price (93%), electrical energy consumption (50x) and carbon emissions (50%). With this course of, Intecells is promising the printing of electrodes for any chemistry at any scale, whereas aligning with its prospects to construct battery cells in line with their design. And, Gayden says, the design may appear to be something.

“The shape issue’s key for consumable wearables. So, our expertise won’t solely make a smaller, thinner battery, we are able to make it a versatile, irregular form,” she says. “The form could be modified, could be conforming to your product kind issue. That’s not attainable as we speak. From wearables to automobile batteries, the product is designed across the battery. The battery takes up prime actual property in your product. That’s what we’re going to influence. Open up the house, the design choices, design every kind of shapes which might be extra engaging.”

Intecells is hoping to allow a few of these new-look battery merchandise at scale by 2024. The corporate views itself having a sizeable influence within the automotive house, although a prolonged testing course of to make sure the batteries carry out as promised in all seasons will delay its entry into this market. As an alternative, Intecells desires to first make its mark within the shopper merchandise house.

Learn extra | Charging up: the rising use of 3D printing for battery functions

“It’s simply simpler. We will absolutely show all the advantages or attributes [of our battery technology] – kind issue, price, vitality density – it’s a great platform to show the advantages of this expertise for automobile folks to see the expertise mature in digital market. [Then,] they’ll think about how this may profit them. It’s a great entry. It is sensible, engineering smart, to stroll earlier than you run.”

Although its battery merchandise received’t be put in in business autos for a while, such is the size of design and manufacturing cycles in automotive, Intecells is already working with prospects within the business, per Gayden. In the meantime, discussions are additionally underway with electronics, wearable and different shopper items corporations.

The intention of Intecells, as Gayden sees it, is to ‘change the basics and the DNA’ of battery manufacture. And that is the place it begins.

“We’re altering the development as a result of we’re going to drive the business in the direction of a distinct manufacturing future the place there’s low carbon, low vitality consumption, low price, serving to the setting, eliminating the limitation for merchandise for shoppers,” she finishes. “Take batteries out of the fee equation as a result of proper now, battery prices an enormous share. Minimise the fee and there’s lots of new merchandise which have but to be imagined, that aren’t attainable as we speak. Lots of new innovation will come from this functionality.

“We all know it really works, to some extent, however we don’t know the way a lot we are able to do, how far more is feasible. As a start-up, we’re in the beginning of that journey. I at all times inform my folks I received’t be there when all these prospects change into actual, we’re simply getting began. However the potential is large and individuals who work with us realise that that is the start.”

Wish to talk about? Be a part of the dialog on the Additive Manufacturing World Neighborhood Discord.

Get your FREE print subscription to TCT Journal.